Cutting the environmental impact of research

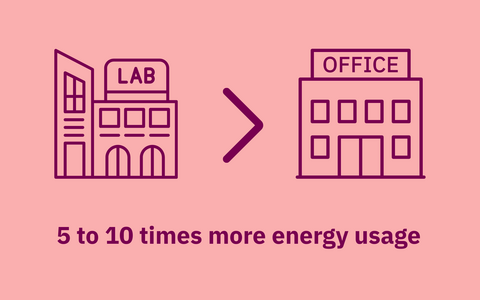

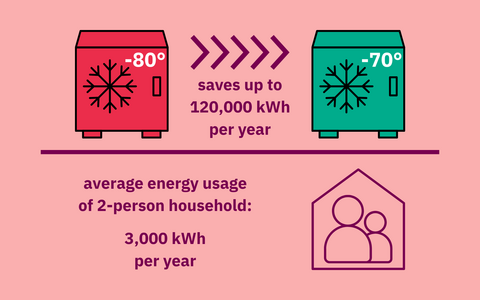

Consuming 5 to 10 time more energy per square meter than standard office spaces, biomedical research labs have a substantial carbon footprint. Equipment like −80 degree C freezers use as much energy per year as a small German household, according to a 2023 study published in PLOS. Additionally, bioscience research is responsible for nearly 2% of global plastic waste.

The Max Delbrück Center is no exception. We produce the equivalent of about 20,000 tons of CO2 each year – by working here, one is effectively doubling their CO2 footprint. But under Sustainability Officer Christian Panetzky and his predecessor Dr. Michael Hinz, we have started to implement several measures to reduce our energy consumption. Our goal is to become greenhouse gas neutral by 2038.

Sustainability Officer Christian Panetzky (on the left) with representatives from the labs with the LEAF certificates.

Making our labs greener

Among these measures is compliance with the Laboratory Efficiency Assessment Framework (LEAF), a sustainability initiative developed by University College London aimed at enhancing laboratory environmental performance. LEAF offers an online platform to guide labs through actions that focus on consuming less energy and water and reducing plastic waste. Laboratories anywhere can achieve Bronze, Silver or Gold certifications based on the number and complexity of sustainability actions they implement.

This year, the first four of our labs attained Bronze: Sander, Poulet, and both Rajewsky labs. “Bronze is about taking small steps to get used to certain practices,” says Dr. Alexis Shih in the Pancreatic Organoid Research and Disease Modeling lab of Professor Maike Sander. The lab for example, and cleaned out its sample inventory and as a result, was able to decommission three refrigerator/freezers. The Poulet lab was also able to reduce its energy use by sharing freezers with other labs. And since 2024, all labs have actually adjusted their ultra-low freezer temperature to -70 degrees C, because they had found that a 10 degree difference did not affect performance.

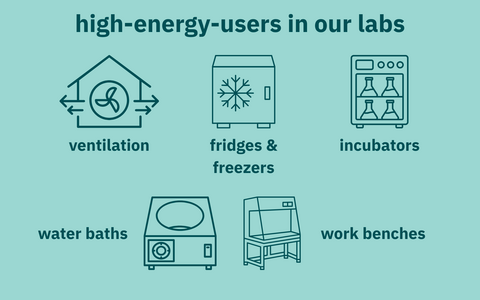

“Many of the actions involve looking at what equipment uses a lot of energy and trying to find ways to reduce the impact,” Shih adds. Data storage, for example, also consumes a lot of energy. Shih now tries to backup only data that is absolutely necessary and avoids duplicating files. Many labs have also implemented other sustainability actions tailored to their specific work, such as choosing to purchase sterile pipette tips that are packaged in boxes that can be partially recycled.

Reducing environmental impact isn’t the only benefit of LEAF. One task on the Bronze certification list, for example, requires labs to do periodic checks of all instruments and reagents to ensure they are adequately calibrated and labeled and that none are expired. Experiments that fail because of avoidable mistakes use a lot of resources, Shih adds, because they must be repeated. “Any researcher would want to ensure the quality and reproducibility of their research. It’ just good science.”

Tools and changing people’s mindset

To calculate energy usage and plastic waste, the LEAF platform offers online calculators. But Katrin de la Rosa's team, led by Lisa Spatt and Mikhail Lebedin, have taken the exercise even further. They measured the energy consumption of every device equipped with a standard plug in their lab. To their surprise, they found that the 230V devices alone consume well over 220 kWh per week – the same amount of energy required to fully charge two Teslas. This value does not include the largest energy consumers such as ultra-low temperature freezers and building services equipment.

In fact, ventilation systems usually account for the largest chunk of a lab’s energy use. That’s because many Max Delbrück Center labs exchange air eight times an hour as part of a safety feature. The certified labs in our more modern facilities, however, can control the air exchange manually, which ensures the highest setting is used only when necessary. This is especially important during weekends, when the labs are largely empty.

But perhaps the biggest change wrought by the program is in the way that people think. The Poulet lab, for example, uses isoflurane gas to anesthetize research animals. Isoflurane is also a potent greenhouse gas. With some investigation, Dr. Svenja Steinfelder, Lab Manager in the Poulet lab, figured out a way to return excess gas collected in a filter system back to the supplier. It can then be reprocessed into new isoflurane gas. While this measure is not part of LEAF certification, the process of going through the LEAF check list has made her think about all the additional ways the lab can conserve resources, she says.

“Achieving Bronze does not take a lot of effort,” adds Steinfelder. “Much of the focus is on raising people’s awareness of our energy usage and to get people thinking about ways to conserve.”

Expanding LEAF to other labs

The Bronze tier is a brilliant way to get our lab teams thinking about the impact of their day-to-day work and where they can optimize.

“The Bronze tier is a brilliant way to get our lab teams thinking about the impact of their day-to-day work and where they can optimize – without piling extra work on anyone,” says Panetzky. “Frankly, every one of our labs could hit Bronze with very little effort.”

By the end of 2026, Panetzky and his team would like at least half of all Max Delbrück Center labs certified Bronze. To achieve that goal, Panetzky’s team will approach labs systematically and encourage them to join LEAF. At the Summer Science Day on July 3, as well as at the quarterly Sustainability Ambassadors meeting, to which each lab and department is requested to send a delegate, results will be showcased.

Although there are currently no plans to make LEAF compliance mandatory in Germany, labs applying for international grants will quickly notice that funding institutions such as Cancer Research U.K. and the Wellcome Trust among others, now require a green-lab certificate just to submit an application, Panetzky notes.

Going for Gold

All labs should of course aspire to Silver or Gold LEAF status, Panetzky says, which are more demanding. Labs are required to implement best practices for using fume hoods and safety cabinets, check the energy efficiency of software code, or cut and reuse consumables even further, among other measures.

“Getting all labs on board will take real initiative and more time,” he adds. “This is a long-term goal and perhaps we can encourage it by rewarding the extra effort. Letting labs keep a share of any energy and resource savings they generate could be the way to go. Incentives like that turn sustainability into a win-win for science and the budget.”

Text: Gunjan Sinha